Variant Fin Tubes

With more than 20 years of experience in HVAC industry and utilizing several modern machinery, Sabafarin company is now manufacturing and utilizing various fin tubes for producing air coolers, air heaters and oil coolers for the following industries:

- Refineries

- Power Plant

- Steel Plants

- Petrochemical

- Textiles

- Food & Chemical Plants

- Diesel Engines

- Compressors

The Various Types Of Fin Tubes Manufactured In Sabafarin Company are as Follows:

- L-Foot Tension Wound Finned Tubes;

- Edge Tension Wound Finned Tubes (K-Fin);

- Wire Finned Tubes;

- Extruded Finned Tubes;

- Elliptical Tube With Rectangular Fins.

L-Foot Tension Wound Finned Tubes :

L-foot tension wound finned tubes are an economical solution for applications requiring greater resistance to vibration and heat cycling typical of air cooled heat exchangers.

L-foot tension wound finned tubes are an economical solution for applications requiring greater resistance to vibration and heat cycling typical of air cooled heat exchangers.

The L-foot design mechanically locks the fins and provides broader contact surface between tube and fin.

L-foot or shoulder tension construction assures uniform finspacing. The fins are rigidly interlocked as the fin radius overlaps with the exposed shoulder edge.

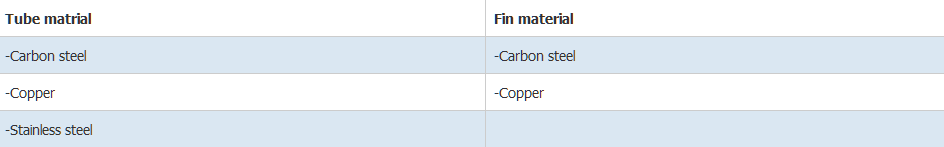

Specifications

Edge Tension Wound Finned Tubes (K-Fin):

Fins are in form of aluminum, copper, carbon steel and stainless steel straps. K−Fins are fastened around the tubes with specific tension force, increasing the heat transfer rate by applying a pressure between the milled edges of fins and the tubes. In steel fins, soldering can be used to completely fix the fins and tubes and increase heat transfer efficiency.

Fins are in form of aluminum, copper, carbon steel and stainless steel straps. K−Fins are fastened around the tubes with specific tension force, increasing the heat transfer rate by applying a pressure between the milled edges of fins and the tubes. In steel fins, soldering can be used to completely fix the fins and tubes and increase heat transfer efficiency.

Hot dip galvanizing of steel fin tube causes a metalic connection between fins and tubes and prevents corrosion of fins and tubes.

Edge tension wound finned tubes offer a low cost solution for low to moderate temperature applications.The surface of the tube is knurled as the fin is wound tightly on the edge around the O.D. of a tube to ensure proper fin to tube contact.

Edge tension wound finned tubes are commonly used in applications with small amounts of vibration.

Edge tension finned tubes are available in similar or dissimilar metals. Edge tension finned tubing is recommended for moderate duty in normal ambient air applications and on most low−temperature air cooled heat exchangers.

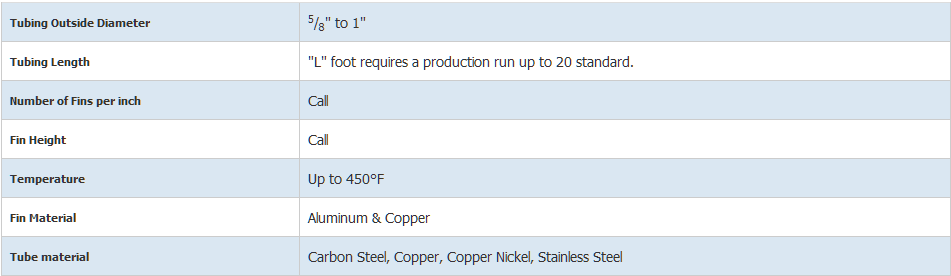

Specifications

Wire Finned Tubes:

Wire wound finned tubes are manufactured at Sabafarin co. by advanced finning machines. Our machines are capable of finning tubes in lengths of up to 6 meters. We make wire wound finned tubes with base tubes of carbon steel,stainless steel, copper and copper alloys like cupro−nickels, admiralty brass, and aluminum brass with copper wire fins and stainless steel wire fins.The base tubes of our standard wire wound fin tubes range from 3/8" to 1½" with fin heights ranging from 5mm to 20mm. Wire wound fin tubes are used in manufacturing compact heat exchangers such as air coolers , air cooled oil coolers, air heaters, and air to air heat exchangers. For manufacturing of wire wound fins, loops of wire are wound helically around the tubes. The fin roots are simultaneously soldered to the outer surface of tube. The air flowing over the fin tubes goes round about the ’legs’ of the fin loop causing immense turbulence. The root soldering eliminates almost all air gaps between the fins and the tube. When coupled with high turbulence, this results in high air side heat transfer coefficient. The air side heat transfer coefficient for wire finned tubes has the highest value compared to any other type of fin tube for identical areas and parameters. The loop density and wire diameter can be varied to give the optimum surface for specific heat transfer and pressure drop requirements. Wire wound fin tubes for use in air cooled oil coolers are offered with internal fins selected from wide variations in configuration. The wire loop secondary surface gives these finned tubes excellent heat transfer characteristics because of its ability to promote turbulence in the fluid passing over it and thereby reducing the tendency for boundary layer formation. Maximum operating temperature for these fin tubes is 480°F.

Wire wound finned tubes are manufactured at Sabafarin co. by advanced finning machines. Our machines are capable of finning tubes in lengths of up to 6 meters. We make wire wound finned tubes with base tubes of carbon steel,stainless steel, copper and copper alloys like cupro−nickels, admiralty brass, and aluminum brass with copper wire fins and stainless steel wire fins.The base tubes of our standard wire wound fin tubes range from 3/8" to 1½" with fin heights ranging from 5mm to 20mm. Wire wound fin tubes are used in manufacturing compact heat exchangers such as air coolers , air cooled oil coolers, air heaters, and air to air heat exchangers. For manufacturing of wire wound fins, loops of wire are wound helically around the tubes. The fin roots are simultaneously soldered to the outer surface of tube. The air flowing over the fin tubes goes round about the ’legs’ of the fin loop causing immense turbulence. The root soldering eliminates almost all air gaps between the fins and the tube. When coupled with high turbulence, this results in high air side heat transfer coefficient. The air side heat transfer coefficient for wire finned tubes has the highest value compared to any other type of fin tube for identical areas and parameters. The loop density and wire diameter can be varied to give the optimum surface for specific heat transfer and pressure drop requirements. Wire wound fin tubes for use in air cooled oil coolers are offered with internal fins selected from wide variations in configuration. The wire loop secondary surface gives these finned tubes excellent heat transfer characteristics because of its ability to promote turbulence in the fluid passing over it and thereby reducing the tendency for boundary layer formation. Maximum operating temperature for these fin tubes is 480°F.

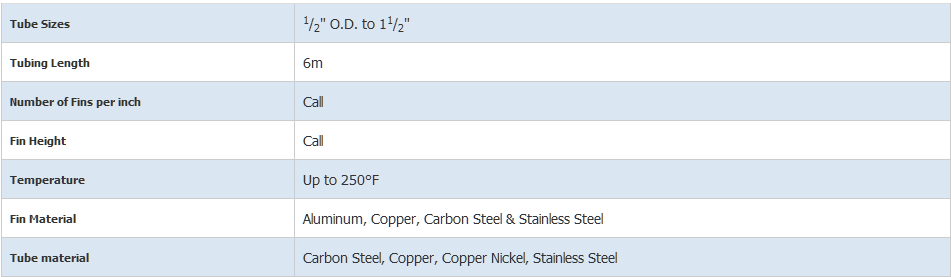

Manufacturing Details:

-

Maximum Fin Height-20mm

- Maximum Tube Diameter-1½"

- Base Tube Materials-Copper, Copper alloys, Carbon steel, Stainless steel.

- Standard Wire Material-Copper, Stainless steel.

- Maximum Tube Length-6m

Extruded Finned Tubes:

p style="text-align: justify;">  Aluminum fins are formed from a bimetallic tube consisting of a base tube and an aluminum muff tube. The fins are formed on a cold rolling process from the wall thickness of the aluminum muff tube . Extruded fin gives very good corrosion protection to the base tube, as the base tube is not visible to the atmosphere in between the fins. Maximum operating temperature for extruded finned tube is 600 °F. As a result, the tube's base is completely connected to the main tube. Since these fins never break, deform or loosen, their heating efficiency does not change over time.

Aluminum fins are formed from a bimetallic tube consisting of a base tube and an aluminum muff tube. The fins are formed on a cold rolling process from the wall thickness of the aluminum muff tube . Extruded fin gives very good corrosion protection to the base tube, as the base tube is not visible to the atmosphere in between the fins. Maximum operating temperature for extruded finned tube is 600 °F. As a result, the tube's base is completely connected to the main tube. Since these fins never break, deform or loosen, their heating efficiency does not change over time.

Advantages Of This Fin Tubes:

Elliptical Tube With Rectangular Fins:

p style="text-align: justify;">  This fin tube design utilizes an elliptical shaped tube with an efficient air foil shape to minimize air−side flow resistance. These fins have improved performance characteristics compared to round tube types.The corrosion resistance of these fins will be very high after being hot dip galvanized. These fin tubes are very compact compared to other types of fin tubes and their heat transfer efficiency is significant. In manufacturing of these fin tubes in our company, first the punched fins are filled automatically on elliptical tubes.Thereafter, the fins on both ends of the tubes are fixed, and fins are connected to the tubes by two different methods. The first one is by fixing the fins to the tubes by mechanical expansion of the elliptical tubes. In the second method, the tubes are dipped in melted zinc tanks. The gap between the fin and the core tube is filled completly by zinc. The maximum working temperature in these fins is 400°C.

This fin tube design utilizes an elliptical shaped tube with an efficient air foil shape to minimize air−side flow resistance. These fins have improved performance characteristics compared to round tube types.The corrosion resistance of these fins will be very high after being hot dip galvanized. These fin tubes are very compact compared to other types of fin tubes and their heat transfer efficiency is significant. In manufacturing of these fin tubes in our company, first the punched fins are filled automatically on elliptical tubes.Thereafter, the fins on both ends of the tubes are fixed, and fins are connected to the tubes by two different methods. The first one is by fixing the fins to the tubes by mechanical expansion of the elliptical tubes. In the second method, the tubes are dipped in melted zinc tanks. The gap between the fin and the core tube is filled completly by zinc. The maximum working temperature in these fins is 400°C.

Advantages of This Fin Tubes:

- It has a very long life compared to other fin tubes.

- The steel fins are not sensitive to typical mechanical loads, for example hailstorm or walk on the bundles.

- Hot dip galvanization provides corrosion protection.

- No-flow regions are avoided by different first and second row fin pitch.

- Simple cleaning using high pressure water.

- Compact design with high extended surface area ratio.